Cummins brands UK-built 6.7-litre hydrogen engine “success” and is “ready to go”

Cummins has completed Project Brunel, a UK-backed engineering initiative to develop a 6.7-litre hydrogen internal combustion engine (H2-ICE) for commercial vehicles.

The company says the new powertrain is “ready to go” and has been a “success”, reinforcing its belief that hydrogen combustion engines have a strong future in transport.

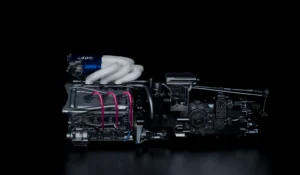

The engine, which has been developed at Cummins’ Darlington facility in partnership with Johnson Matthey, PHINIA, and Zircotec, is based on Cummins’ well-established B6.7 diesel engine platform, but reworked to run on hydrogen.

The project focused on improving performance and durability, with PHINIA contributing new fuel injection technology, Johnson Matthey developing emissions control catalysts, and Zircotec working on hydrogen barrier coatings to handle some of hydrogen’s more volatile properties.

A familiar powertrain, with hydrogen fuel

Unlike some zero-emission alternatives that require entirely new vehicle designs, H2-ICE technology integrates more easily into existing platforms, allowing operators to transition to hydrogen without rethinking their entire fleet.

The spark-ignited 6.7-litre engine meets Euro 7 emissions standards, cutting carbon emissions by over 99% while achieving what Cummins describes as “ultra-low NOx”.

Jonathan Atkinson, Cummins’ Executive Director – Product Strategy, framed it as a “viable, familiar power option” for commercial operators who need zero-carbon fuel while keeping conventional engine architecture.

He also noted that government policy should recognise H2-ICE’s role beyond 2035 and 2040, aligning with other global markets, like the EU and Japan.

Cummins is not alone in this push – JCB, which has been developing its own hydrogen combustion engines for construction and agricultural machinery, has been vocal about the economic advantages of H2-ICE.

Lord Bamford, Chairman of JCB, has argued that hydrogen combustion engines are “highly reliable” and “not inflationary” compared to battery-electric alternatives, as they utilise existing supply chains and manufacturing expertise, rather than relying on scarce and costly materials like lithium and cobalt.

Scaling up hydrogen combustion

At an event at Cummins’ Darlington site, the project’s partners showcased the engine and discussed its commercial potential.

Initially it has been designed for medium-duty trucks and buses, but the 6.7-litre platform is scalable – Cummins is already developing a 15-litre hydrogen engine for heavy-duty vehicles, construction, and agricultural machinery.

Dr. Simon Godwin of PHINIA said the project has strengthened the UK’s hydrogen combustion ecosystem, while Matt Shillito from the APC highlighted the role of H2-ICE in keeping UK engine manufacturing competitive as the industry transitions to cleaner fuels.

The scalability of H2-ICE tech also means off-highway applications – agriculture, mining, and construction – are likely candidates.

In these industries, battery-electric solutions face significant challenges due to high power demands and remote locations where charging infrastructure is impractical.

How H2-ICE fits into the hydrogen debate

Hydrogen internal combustion is one of several competing technologies in the race to decarbonise transport, alongside hydrogen fuel cells and battery-electric powertrains.

Some firms like Volvo, Daimler, and others have prioritised hydrogen fuel cells for long-haul trucking, Cummins is betting that H2-ICE offers a more familiar, cost-effective transition path – especially for fleet operators who want to avoid the higher upfront costs of battery-electric and fuel cell trucks.

However, for H2-ICE to succeed, hydrogen refuelling infrastructure needs to expand significantly.

While fuel cell trucks and combustion hydrogen trucks can share refuelling stations, the UK currently has very few hydrogen refuelling locations – a challenge that must be addressed if Cummins’ vision is to become a reality.

A serious investment in hydrogen combustion

Cummins is backing the technology with a £13 million investment in a new Powertrain Test Facility at Darlington, expanding its test capabilities across hydrogen, natural gas, diesel, and battery-electric powertrains.

Meanwhile, UK government policy remains uncertain on hydrogen combustion’s long-term role.

The EU and Japan have explicitly included hydrogen ICE in their decarbonisation strategies, but the UK has yet to clearly define whether hydrogen combustion will be treated as a zero-emission solution beyond 2035.

For now, Cummins is confident: the 6.7-litre hydrogen engine is built, tested, and, by its own assessment, “ready to go”.