JCB are building the future with hydrogen engines

With over 120 hydrogen engines produced so far, JCB is leading the way when it comes to developing the future of green energy in both the construction and agricultural industry.

At the heart of this innovation is JCB Power Systems in Derbyshire, where over 150 engineers are dedicated to developing advanced hydrogen combustion engines, JCB has already produced more than 120 of these engines.

The hydrogen engines are currently being tested in various machines to ensure efficiency and performance.

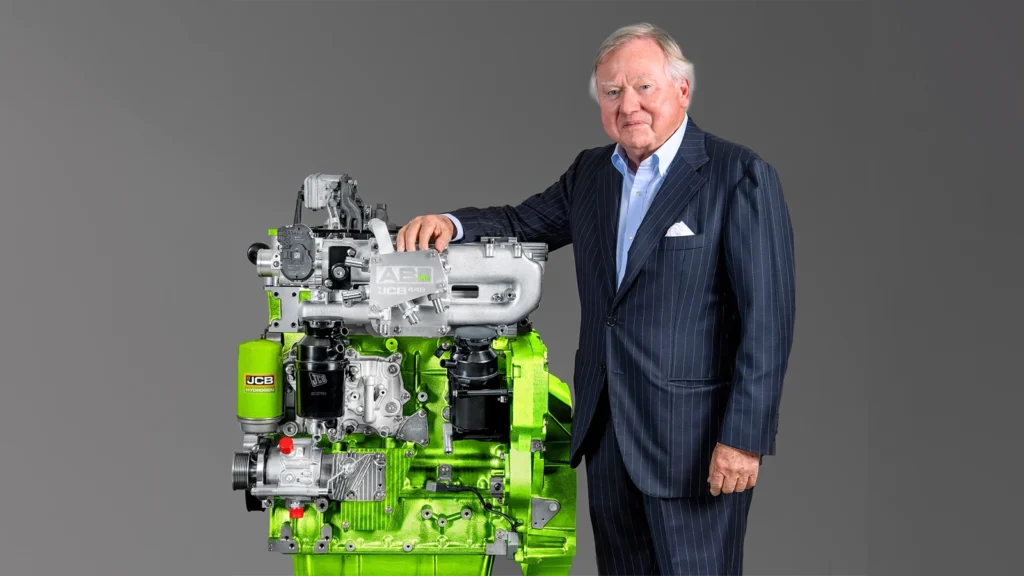

JCB Chairman, Lord Bamford, who is personally leading the company’s hydrogen initiatives, shared insights into JCB’s journey towards sustainable machinery.

He noted that while JCB has successfully launched over 20,000 battery-electric compact machines, heavier equipment poses different challenges.

The high energy demands and long operational hours of such machinery make battery-electric solutions impractical, especially in remote areas with limited access to electrical grids.

Lord Bamford expressed his enthusiasm for the progress made by JCB’s engineers, stating, “[We’re] developing zero-carbon solutions for future machinery.

Our hydrogen engines are a super-efficient, affordable answer to the need for fossil fuel alternatives in construction and agriculture, and they can be rapidly brought to market using our existing supply base.”.

JCB’s Hydrogen Combustion Engine

The hydrogen engine that JCB has developed is an internal combustion engine, with power combusted and delivered in the exact same way as a diesel engine.

JCB claims that their technology is far less complicated than hydrogen fuel-cell technology, where storage and transportation is complex. Most importantly, nothing but steam is emitted from the tailpipe and zero CO2 at the point of use.

JCB’s commitment to zero-emission technology comes as global governments push for infrastructure that supports hydrogen as a means to reduce carbon dioxide emissions.

Since 2004, JCB has been at the forefront of engine manufacturing, producing around 200 engines per day at its Derbyshire plant in the UK and another 200 per day at its Delhi plant in India.