BREAKING: BMW puts a date on hydrogen – fuel-cell production confirmed for 2028

BMW has been chasing hydrogen for nearly fifty years. It has built hydrogen-powered 7 Series saloons, prototypes running on liquid hydrogen, and, most recently, a fleet of iX5 SUVs with hand-built fuel-cell systems.

Clever cars, engineering showpieces – but none of them ever rolled down a production line…

Until now.

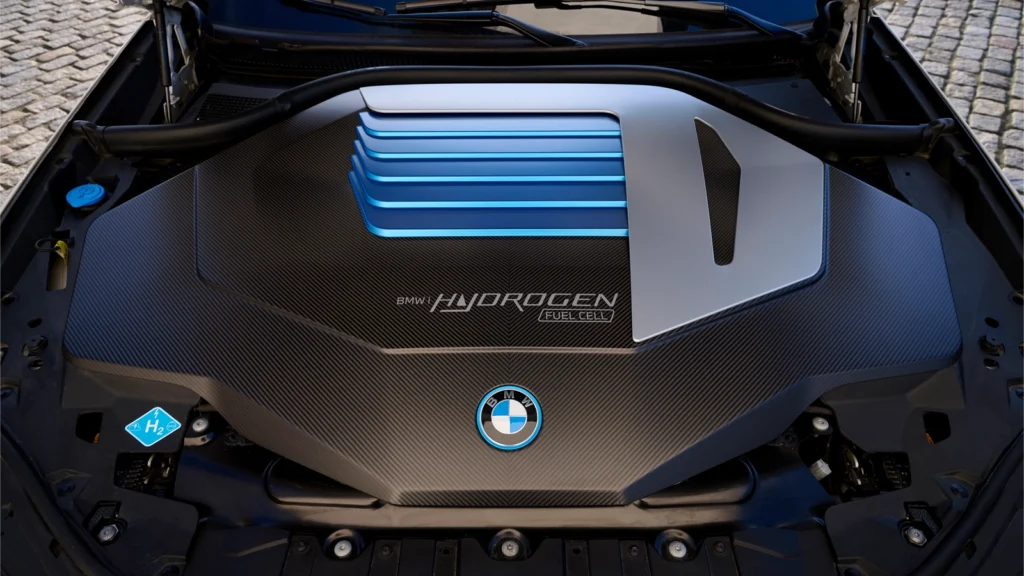

BMW has confirmed it will start mass production of its hydrogen drivetrains at Plant Steyr in Austria, putting a date on its third-generation fuel-cell system entering full-scale production in 2028.

Tooling is being installed, new assembly lines are being built, and BMW has put hydrogen firmly on its product roadmap.

The new system – the first BMW fuel-cell drivetrain designed for large-scale manufacturing – is already being built in prototype form at its hydrogen competence centres in Munich and Steyr.

After decades of experiments, hydrogen is moving out of the lab and into BMW’s core business. As BMW’s hydrogen boss told Driving Hydrogen earlier this year, “the timing is right.”

Europe’s hydrogen hub

To make this complex mix of chemistry, electronics, and precision engineering work at scale, BMW has reshuffled parts of its operation.

Munich will remain the engineering base, where prototypes are assembled, tested and signed off. Steyr, a plant with decades of engine-building experience, is being prepared for hydrogen production with new lines, rigs and infrastructure ahead of the 2028 launch.

Landshut will produce the hard parts, including the Energy Master – a control unit that manages power between the fuel cell and high-voltage battery at up to 800 volts – along with the stack housing and pressure plates. Dingolfing is building prototype Energy Masters, drawing on lessons from the Neue Klasse EV electronics programme.

BMW says hydrogen drivetrains will be manufactured with the same standards and processes used for its engines and battery packs.

What’s changed under the skin

The new system is 25% more compact than the hardware in today’s iX5 Hydrogen demonstrators but delivers more power and greater efficiency.

BMW says this comes from a jump in power density, a fresh approach to packaging, and smarter operating strategies.

All supporting systems – hydrogen delivery, compressors, cooling loops, safety hardware – are integrated into a single module that can fit into existing platforms without compromise.

Toyota continues to supply the individual fuel cells, but BMW has engineered the complete system in-house.

The two companies are now co-developing stack chemistry for both passenger and commercial vehicles, with an emphasis on making hydrogen repeatable, scalable and affordable.

BMW’s “technology open” plan

“The launch of the first-ever fuel cell production model from BMW in 2028 will add another exceptionally efficient high-performance drive system with zero emissions to our technology-open product portfolio,” said Joachim Post, BMW AG Board Member for Development.

“We are proud to be producing another innovative drive technology at Plant Steyr in future alongside the latest generation of electric motors and combustion engines,” added Klaus von Moltke, Senior Vice President Engine Production.

Fifty years of groundwork

BMW’s hydrogen story started in the 1970s with a hydrogen 5 Series powered by a modified combustion engine running on liquid hydrogen.

Through the ’80s and ’90s came more experimental 7 Series saloons, culminating in the Hydrogen 7 limousine of 2006 – a V12-powered showcase for hydrogen engineering.

The company pivoted to fuel cells in the 2010s, partnering with Toyota to accelerate development.

In 2014, BMW built a 535iA mule fitted with Toyota’s early stack, which led to the second-generation system in today’s iX5 Hydrogen fleet.

Those SUVs are hand-built, expensive and heavily engineered, proving hydrogen’s potential, but highlighting the need for a system that could be built by the thousand.

The third-generation system is designed to solve that problem.

How a BMW fuel-cell car works

A hydrogen fuel-cell car is effectively a water synthesising power station on wheels. Hydrogen gas, stored at 700 bar in carbon-fibre tanks, is fed into a ‘stack’ of membranes where it reacts with oxygen from the air, to make water, and as a byproduct of that reaction, generates electricity.

The only thing leaving the tailpipe is water vapour. That electricity powers an electric motor, and a small high-voltage battery handles energy recovery and load balancing.

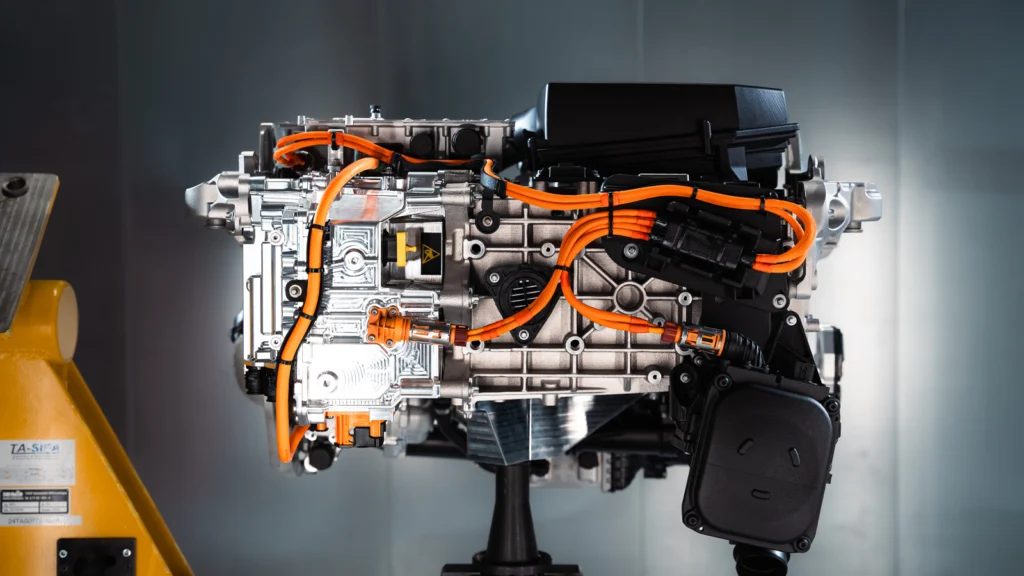

BMW’s third-generation system integrates the entire drivetrain – the stack, cooling hardware, sensors, pumps, compressors and power electronics – into one module.

Engineers in Munich are currently validating it to production standards, using the same industrialisation process they’d apply to a combustion engine or EV powertrain.

Neue Klasse and beyond

This is BMW’s “technology-open” mantra in practice. Next year the Neue Klasse EVs will hit showrooms, trusty old combustion engines will stay in the mix. And in three years’ time, a hydrogen-powered BMW will roll out of Steyr.

After half a century of prototypes, BMW has a plant, a supply chain and a date. Hydrogen BMWs are finally going into production.