JCB earns landmark approval for hydrogen engines across Europe

JCB’s hydrogen engines are ready to do some heavy lifting – not just in the lab, but now on construction sites and farms across Europe.

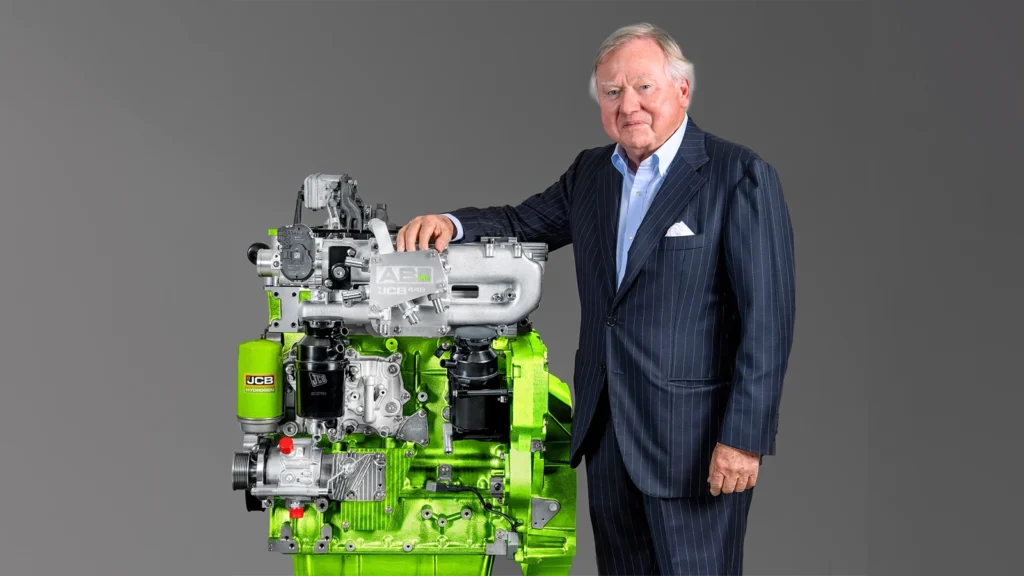

After three years, £100 million quid, and countless cups of tea, the world’s first “fully operational hydrogen combustion engine developed by a construction equipment company” has been signed off by 11 licensing authorities.

The Netherlands’ Vehicle Authority RDW was the first to give its official stamp, followed by Great Britain, Northern Ireland, Germany, France, Spain, Belgium, Poland, Finland, Switzerland, and Liechtenstein. More approvals from additional nations are expected in 2025.

JCB Chairman Lord Bamford said: “This formal certification paves the way for the sale and use of hydrogen engines right across the UK and Europe.

“I couldn’t have hoped for a better start to the year. Most of all, I’m delighted for our team of British engineers who’ve worked tirelessly to reach this stage.”

Hydrogen internal combustion engines

Hydrogen combustion engines might not grab the same attention as their hydrogen fuel-cell cousins, but JCB’s made a compelling case for why they’re ideal for heavy-duty machinery.

“These machines have to do a full day shift, at least, and that means eight hours a day,” Bamford explained.

“A battery isn’t the right solution for this sort of machinery. Hydrogen machines can just be refuelled and put back out to work straight away.”

Designed to handle the dust, cold, and heavy loads of demanding environments, JCB’s hydrogen engines deliver the same torque and reliability as their diesel predecessors – without any of the carbon emissions.

From prototypes to production

JCB has already produced 150 hydrogen engines, with 130 of them built on production lines and powering pre-production machines like backhoe loaders, telehandlers, and generator sets.

These machines are currently undergoing rigorous real-world testing on customer sites, with the early feedback proving positive.

Bamford said: “This engine is just as efficient as the diesel engines we make – exactly the same performance, torque, and power, and able to work in all conditions”.

It’s a straightforward switch for operators: keep the engine layout, swap the fuel, and get to work.

Hydrogen refuelling infrastructure

As Bamford pointed out, hydrogen’s success depends on the infrastructure to support it. Unlike diesel, which benefits from over a century of development, hydrogen is still somewhat catching up.

Europe is taking the lead, with an EU directive mandating refuelling stations every 200 km along major routes. The continent also boasts over 260 hydrogen refuelling points – a promising start, but more is needed to meet growing demand.

“Fuel wasn’t really available back then [in the early days of diesel] either,” Bamford noted. “It grew alongside demand. The same will happen with hydrogen.”

For off-highway machines, however, the solution is already here. JCB offers a ‘bowser’ type system – a portable refuelling trailer that brings hydrogen directly to the site where it’s needed.

There’s no need for a fixed fuel station, no reliance on the grid, and no compromise on practicality. Just like diesel bowsers, this approach is perfectly suited to the realities of construction and agricultural work.

JCB’s certification

JCB’s certification milestone is a clear signal that hydrogen combustion engines are ready for real-world deployment.

Batteries have their strengths in light-duty and urban applications, hydrogen shines in heavy-duty scenarios where energy density, quick refuelling, and rugged reliability matter most.

By using conventional engine platforms, JCB offers operators a practical, non-inflationary, low-barrier solution to transition from diesel to hydrogen without re-engineering their fleets.

With certification secured and production scaling up, JCB’s hydrogen combustion engines are on track to hit the market in 2025. It’s a big step for JCB and a clear win for industries looking to decarbonise without compromising performance.