The RAF truck with a Ford Performance engine converted to run on 100% hydrogen

The British Royal Air Force have lent one of their MAN HX 4×4 refuelling trucks to ULEMCo, and the Liverpool firm has promptly gutted it and rebuilt it into a hydrogen-powered hybrid with a Ford sourced V6 engine.

The project, shown off at this year’s Cenex Expo 2025, looks on the outside like any other military green workhorse, but under the bonnet sits a Ford Performance V6 running on nothing but hydrogen gas.

I spent some time with Chris Games, ULEMCo’s Head of Application Engineering, who gave me the full tour – from injectors to inverters, and all the bits in between.

A familiar truck, repurposed

This particular MAN HX used to cart jet fuel around RAF Leeming in North Yorkshire. Now the Jet-A1 tanks are gone, the old diesel lump is out, and it’s in the workshop as a guinea pig.

When it returns to Leeming, it’ll no longer be refuelling Typhoons, but ferrying kit and cargo around the site with its new job as a flatbed.

This conversion job isn’t about frontline combat (yet), it’s about seeing if hydrogen can do the day-to-day jobs reliably.

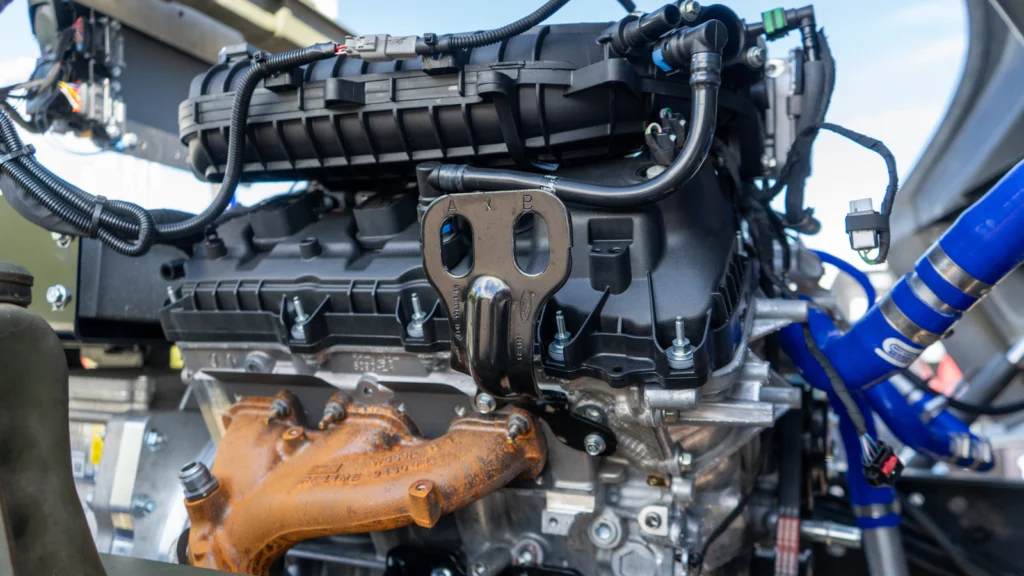

A Ford engine you don’t usually see in khaki

The new heart of the four wheel drive truck is a 3.3-litre Ford-sourced, Performance V6 – the sort of thing you’d expect to see in a Ford Explorer police interceptor, but not in a military truck in North Yorkshire.

“It’s a mass-production engine, quite readily available, just not really in the UK because Ford Performance is more of an American thing, we had to source them from an importer in Europe” Games told me.

In petrol trim it makes more than 120 kW. Here it’s been tamed to about 25-30 kW, and because it’s a range extender hybrid, it sits at a steady 3,500 rpm. “That’s a nice sweet spot for a petrol engine,” Games said. “It’s naturally aspirated – no turbo – and we’re running it well below its design load.”

How you turn petrol into hydrogen power

The conversion is lighter touch than you’d think. The pistons, head, oil, coolant are all standard. What changes are the spark plugs, the injectors and the fuel rail.

Bosch supply off the shelf hydrogen-spec injectors, the rail gets a tweak, and hydrogen comes in at 7 bar rather than 350, fed through PTFE tubes (a bit like push-fit you get at home).

“Those tubes are good for about 15 bar, more than enough, and they’re easier to work with than rigid pipe,” Games explained.

For safety there’s a thermal fuse wired into the injectors. “If there’s ever a backflash – hydrogen igniting back into the intake – the fuse burns and cuts power to the injectors. I’ve not seen one actually blow in six years, but it’s there as a precaution.”

ULEMCo usually deal in the business of converting diesel engines to ‘dual fuel’ operation – effectively they add a hydrogen connection to the intake manifold and mix it with air as it goes in. However this truck is all hydrogen. “There’s no petrol in there at all,” Games said. “It’s 100% hydrogen.”

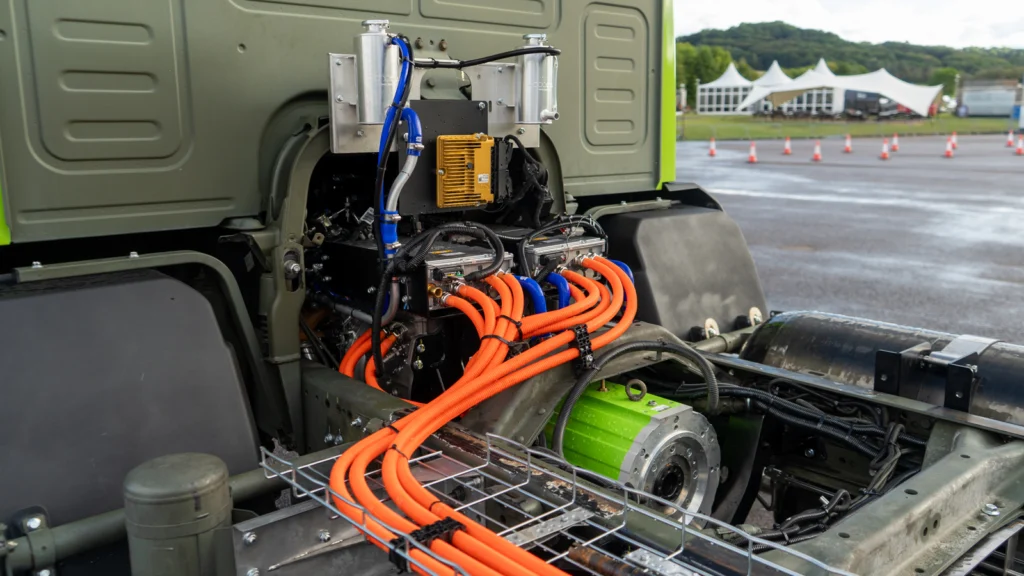

A generator on four wheels

The V6 doesn’t drive the wheels directly, instead it behaves like an electricity generator – like a BMW i3 range extender, even.

The engine spools up a generator, which makes electricity, which then pushes current through an inverter into a buffer battery.

Another inverter meters it back out into a large traction motor sitting between the chassis rails, which then feeds the truck’s factory-standard transfer case and axles just like before.

“It’s a simpler way of doing it than motors on each wheel,” Games said. The downside is the motor isn’t massive, so while the truck won’t be pulling itself up a rocky incline, that’s not the brief. At Leeming, it just needs to shuttle gear around the airfield.

Cooling and reliability

Hydrogen burns pretty hot, but Chris says cooling has been pretty straightforward. The engine still uses its original radiator, and the electronics have their own, only because they run a different coolant fluid.

In practice, the V6 only cuts in when the battery charge dips, so it rarely runs flat-out, so rarely gets too hot.

On long-term reliability, Games was pragmatic. “If you were running this engine flat out as the sole source of power for thousands of hours, you might eventually see some degradation or embrittlement. But at low output, steady revs, we’ve not had any issues.”

In Liverpool, ULEMCo has a sister engine running on the dyno. “It’s clocked up a few hundred hours. We’re using it to map efficiency across load points, not just for durability.”

A year in the making

Getting to this point has taken close to a year, but next time, ULEMCo expects it’ll be quicker. “Anything similar will be easier,” Games said. “We’re trying to make the system as flexible as possible so it can be applied to other vehicles.”

The firm has also converted an airport tow tug using the older 3.7-litre version of the Ford engine, and some ambulances at Teesside Airport are now being fitted with the same 3.3-litre V6 that will also run on hydrogen.

“The aim is modularity,” Games explained. “If you want a hydrogen engine, we can do that. If you want a fuel cell, we can do that too – using the same platform and control system.”