Bosch brings hydrogen engines and low-emission kit to Bauma 2025, confirms 100+ H2 projects in motion

Bosch is at Bauma this week with a full spread of low-emission powertrain tech for construction machines – including new hydrogen engines, electrification systems, and something called a “Digital Fuel Twin” for tracking renewable fuels.

The company says it’s already working on more than 100 hydrogen engine development projects globally, with the first commercial applications due this year.

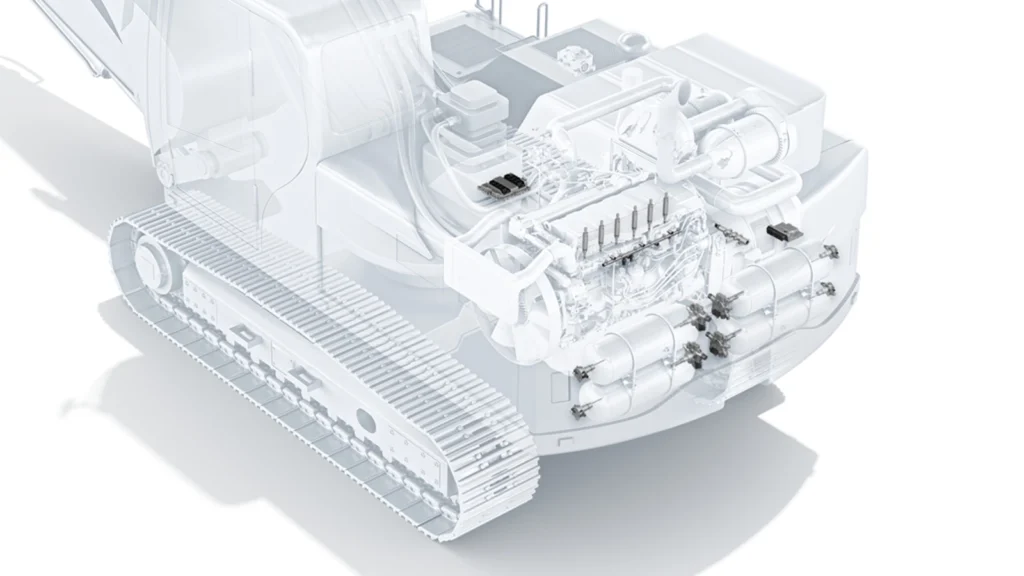

These engines use Bosch injection systems and are designed for high-efficiency operation under heavy loads – ideal, the company says, for the kind of stationary or high-demand tasks construction kit tends to face.

According to Bosch, around 80 to 90 percent of the tech in these hydrogen engines is carried over from conventional diesel units.

That makes them easier to integrate into existing vehicle platforms – and in theory, more reliable in tough operating environments.

Bosch sees potential for both port- and direct-injection setups, and suggests hydrogen could be a particularly strong fit for mining trucks and other large, high-utilisation machines where space and durability are key.

Drop-in fuels, digitally certified

Bosch is also promoting HVO100 and other renewable synthetic fuels as a quick way to cut carbon emissions from existing fleets.

The company says its current injection systems are already compatible with these drop-in fuels, and its new “Digital Fuel Twin” software can now track their usage – logging everything from fuel origin to filling station, and even issuing digital sustainability certificates for each machine.

The idea is to give operators verified data on the carbon footprint of their fuel consumption, which could be useful for tendering, regulation, or internal reporting.

According to Bosch, the system covers fuel volumes and greenhouse gas savings down to the individual machine.

Electric options too

While most construction machinery will still use combustion engines for the foreseeable future – Bosch reckons 80% of new machines over 56 kW will still be diesel-powered in 2035 – electrification is also part of the picture.

Bosch Rexroth is expanding its eLION electric drivetrain range to support 96-volt systems, while Bosch Engineering is showing off a compact new electric powertrain for 800-volt applications, aimed at machines with high power needs and limited space like wheel loaders.

All three Bosch divisions – Bosch, Bosch Rexroth, and Bosch Engineering – are exhibiting at Bauma in Munich this week. You’ll find them at booths A3/327 and A4/526.