Swapping oil pipes for hydrogen: Exolum’s UK trial of green hydrogen infrastructure

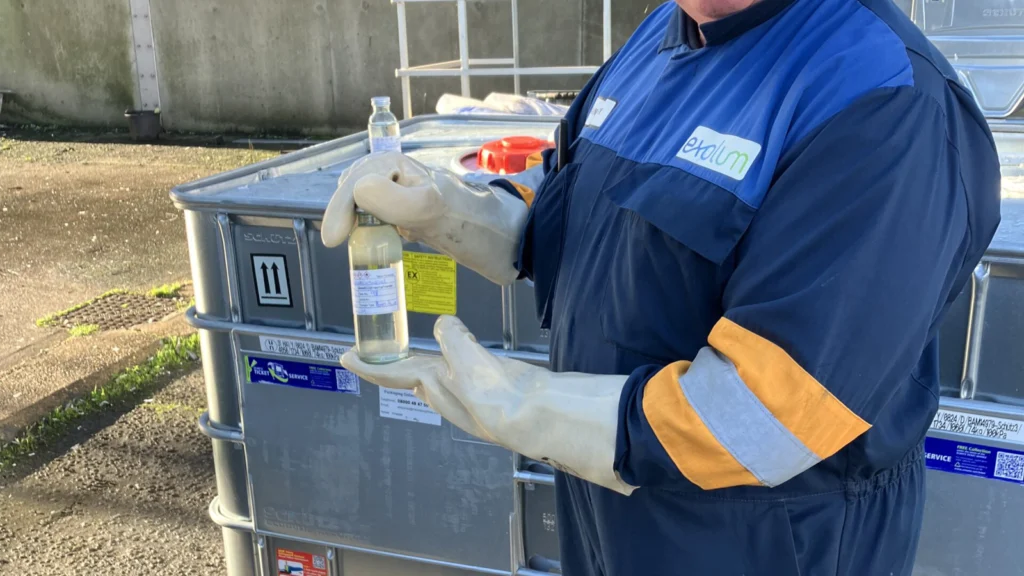

Spanish firm Exolum has launched a bold first for the UK – by repurposing existing infrastructure used for oil to enable green hydrogen storage and transport.

Taking place at the bustling Port of Immingham in Lincolnshire, the project uses “Liquid Organic Hydrogen Carriers” (LOHC) to move and store hydrogen safely in existing pipelines and tanks, offering an infrastructure-light model for hydrogen’s future.

Hydrogen in old oil tanks

LOHCs are, simply put, organic compounds that “carry” hydrogen in liquid form by chemically bonding to it.

Hydrogen, as we know, is the most abundant element in the universe. But the problem is, it likes to stick to other elements, forming compounds.

LOHCs uses this inherent characteristic to its advantage, absorbing and releasing the gas without the pressures and temperatures required of ‘conventional’ hydrogen storage.

Exolum is demonstrating that it’s possible to utilise existing infrastructure from oil tanks and pipelines – and economically repurposing it for clean energy.

Exolum’s Ignacio Casajús, Global Strategy & Growth Lead, explains the intent, saying: “This project proposes a realistic, safe, and affordable approach to hydrogen transport.

“By using what’s already here, we’re creating a model that’s flexible, scalable, and efficient.

“This is a cornerstone for building the hydrogen economy faster and with less disruption.”

Scaling hydrogen where it’s needed most

With £505,000 in funding from Innovate UK’s Hydrogen Storage and Distribution Supply Chain Collaborative R&D program, Exolum is putting 400 cubic metres of LOHC – containing 20 tonnes of hydrogen – through a 1.5km pipeline linking their Immingham East and West terminals.

For context, that’s the hydrogen equivalent of driving a car roughly two million kilometres. Or driving to the moon nearly five and a quarter times.

And Immingham, the UK’s largest freight port, is where the demand is anticipated to rise fastest, from ports to nearby industrial hubs around the Humber region.

UK’s hydrogen strategy

Exolum estimates that its UK network could supply around 4.6 TWh of hydrogen a year by 2030 – enough to meet 30% of the UK’s projected demand.

Notably, this strategy targets hydrogen storage near consumption points, eliminating the costly need to build new storage from scratch.

Immingham is a testbed for what could be a nationwide approach, allowing Exolum to scale up without the typical infrastructure headaches.

While this project puts green hydrogen in the spotlight, Exolum is also working on the broader ecosystem.

Their Tees Valley Hydrogen Vehicle Ecosystem project will soon bring green hydrogen production, a water electrolyser, and a 1.5-tonne-per-day refuelling station to Stockton-on-Tees.

This “hub and spoke” distribution set-up offers flexible hydrogen delivery that scales with demand, directly feeding into the UK’s Clean Power Mission 2030 goals.

Hydrogen in Europe

Over on the continent in Spain, Exolum built Madrid’s first integrated hydrogen production and dispensing plant intended to fuel heavy transport, supporting the decarbonisation of road freight and logistics.

Collaborations like the Regenera and GreenH2Pipes consortia showcase Exolum’s commitment to advancing LOHC technology and renewable hydrogen on a continental scale.

Hydrogen-powered future

Exolum’s LOHC-based storage model could transform hydrogen’s potential by bringing the green hydrogen market to scale faster and more affordably.

Old fossil fuel infrastructure doesn’t have to sit idle but can become the backbone of a hydrogen-powered world, meaning a cheaper and quicker transition towards a hydrogen society – ready for the clean energy demands of tomorrow.