Australian researchers brew up hydrogen from human urine – and say it’s cheaper than fossil fuel

There are no shortage of outlandish hydrogen concepts, but this one’s not taking the p**s, or rather, it is.

Researchers at the University of Adelaide have developed two new electrolysis systems that extract hydrogen from urea – the nitrogen-rich stuff found in human wee – using up to 27% less electricity than splitting water.

And crucially, they say it’s not just efficient, but is even cost-competitive with grey hydrogen.

Purer than it sounds

Traditional electrolysis uses water as a feedstock and electricity to split it into hydrogen and oxygen.

It’s clean – but can be somewhat expensive in practice, especially if you’re paying for renewable power.

In contrast, urea requires significantly less energy to break down, making it an attractive target for low-cost, low-carbon hydrogen.

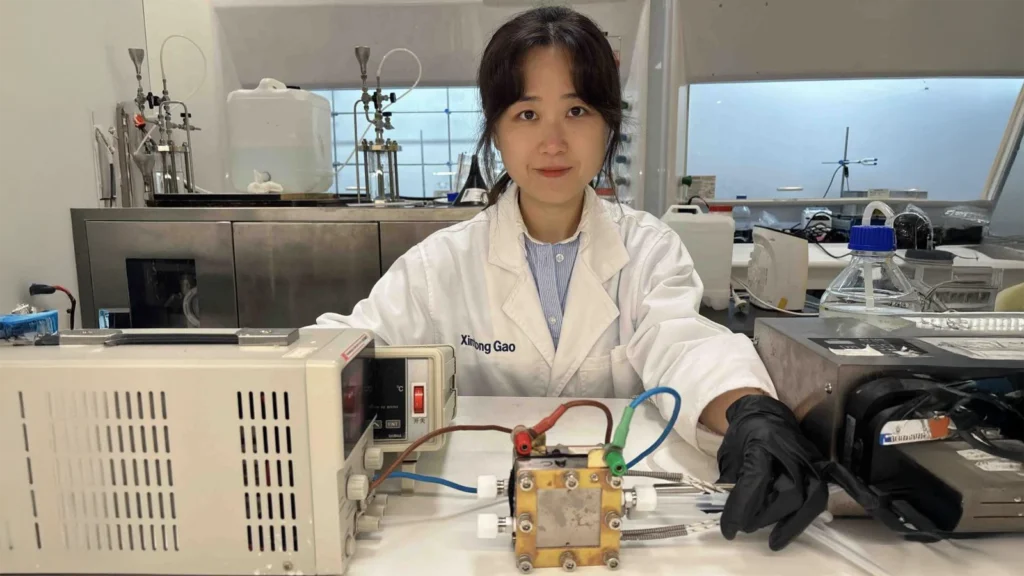

The University of Adelaide research team, working as part of the ‘ARC Centre of Excellence for Carbon Science and Innovation’, built two prototype systems to crack the urea conundrum – one using pure urea, and another using actual urine.

Both are said to avoid the typical by-products – nitrates and nitrites – that can suppress hydrogen production and create toxic wastewater.

Professor Yao Zheng, one of the project leads, said the new systems could produce hydrogen at a price point comparable to – or cheaper than – grey hydrogen made from fossil gas.

Version one: urea from Haber-Bosch

The first setup, published in Angewandte Chemie International Edition, used commercially pure urea – the kind produced industrially using the CO2 intensive “Haber-Bosch” process.

The system is notable for being membrane-free, simplifying the design and using a novel copper-based catalyst to keep costs down.

But using pure urea limits how ‘green’ the hydrogen can really be – which is why the second system aims to bypass the supply chain entirely.

Version two: direct from the source

Published in Nature Communications, the second approach takes things a little more literally. It runs off actual urine – complete with all the chloride ions, salts, leftover beer, and other unwelcome extras that make this kind of electrolysis so tricky.

Normally, those chloride ions would trigger a side reaction that corrodes the anode and generates chlorine gas.

To sidestep this, the team used platinum-based catalysts on carbon supports and developed a chlorine-mediated oxidation mechanism that avoids the worst of the corrosion and keeps the hydrogen flowing.

The result being a system that uses real wastewater as a feedstock, produces only nitrogen gas as a by-product, and consumes 20-27% less energy than water electrolysis. How green is that?

So, what’s next?

As it stands, the second system’s reliance on platinum – expensive, quite rare, and not particularly scalable – makes it hard to roll out at large scale.

But the researchers say they’re working on replacing it with carbon-supported, non-precious metal catalysts that could dramatically reduce costs.

The ultimate goal is a deployable, low-cost electrolysis system that generates hydrogen and helps clean up nitrogen-rich wastewater in one go.

That could prove useful in sectors like agriculture, sewage treatment, and decentralised power – all without relying on fossil fuels or potable water.

Professor Zheng said: “We need to reduce the cost of making hydrogen, but in a carbon-neutral way… We solved this by using a green source of urea – human urine – which is the basis of the system examined in our second paper.”

For once, the phrase “liquid gold” might not be hyperbole.