Where’s the best place in the world to produce green hydrogen? Peaxy says…

“It depends.”

That’s the sort of answer that can make even the calmest project manager twitch a bit. But according to Peaxy CEO Manuel Terranova, there’s no escaping it.

“It depends on a multitude of factors,” he explained, “including your cost of power, local renewable resources, land availability, financing costs, carbon credits – basically, everything from sunshine to spreadsheets.”

Fair enough. Hydrogen economics aren’t exactly straightforward. But while the ‘it depends’ answer is inevitable, Peaxy reckons it doesn’t need to be painful.

To tackle this complexity, the Silicon Valley-based firm has brought its digital twin technology into the hydrogen world, creating a new Hydrogen Digital Twin (HDT) platform aimed squarely at simplifying – and accelerating – the planning process.

The logic here is straightforward enough. When deciding where to build your shiny new hydrogen plant, you’re typically faced with weeks – sometimes months – of back-and-forth number crunching, consultant fees, and late-night emails to your increasingly irritated engineers.

Not exactly ideal when the industry’s trying to rapidly scale up to meet climate goals.

But Peaxy’s software, the company says, shrinks this entire ordeal down to just ten minutes.

How? By using cloud-based simulations and crunching hundreds of different variables – everything from renewable energy costs and wind data, through to hydrogen storage options, financing, and even carbon credits.

Pop in your parameters and out comes a clear, detailed simulation, including that all-important Levelised Cost of Hydrogen (LCOH).

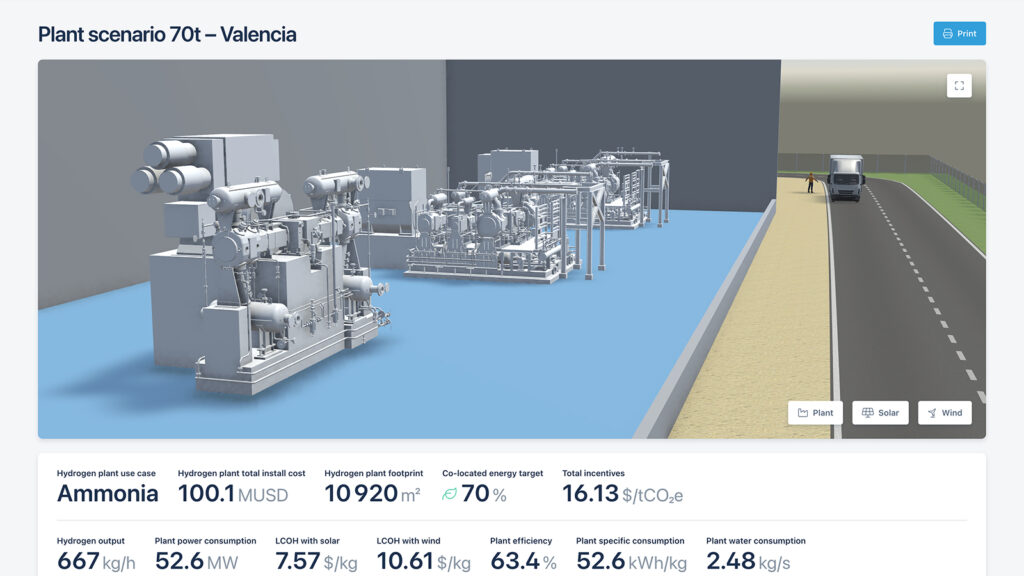

The output from the digital twin also provides a 3D visualisation of the plant and detailed hydrogen production metrics based on first-order physics simulations of the electrolysers and compressors, ensuring accurate, real-world performance predictions.

Terranova summarises it neatly: “Instead of waiting weeks for budget estimates, customers get concrete, actionable insights almost immediately.

It’s about giving clarity, confidence, and speed – exactly what’s needed if we’re serious about scaling hydrogen infrastructure quickly.”

While digital twins might sound fancy, the concept itself is relatively simple. Imagine designing and testing every detail of your plant in a realistic digital model before you pour a single tonne of concrete.

It’s the sort of tech Peaxy has already deployed successfully for the defence sector and complex power generation plants.

Extending that capability to hydrogen – where efficient planning and cost certainty are absolutely crucial – is a logical step.

Of course, the software itself isn’t building the hydrogen economy – it’s the people using it. But anything that takes weeks of number crunching and turns it into clear answers in minutes is likely to be well-received by an industry already tired of lengthy delays and expensive guesswork.

So, yes – it still “depends.” But thanks to Peaxy’s Hydrogen Digital Twin, getting to the answer just became a whole lot quicker.