Toyota’s GR Corolla liquid hydrogen concept: With a nifty trick up its sleeve

Toyota’s GR Corolla H2 Concept has been a motorsport laboratory for the Japanese carmaker, testing and refining their hydrogen technology under race conditions. But at the Super Taikyu Series final in Fuji this weekend, it wasn’t just the car that was catching attention.

Competing in the ENEOS Super Taikyu Series Round 7, the GR Corolla H2 Concept continued its journey running on liquid hydrogen – a switch from gaseous hydrogen that Toyota began earlier this year for the GR Corolla.

Liquid hydrogen offers two distinct advantages: increased fuel density and extended range – essential for endurance racing.

But the GR Corolla wasn’t the only trick up Toyota’s sleeve in Fuji. Alongside the car, Toyota unveiled a separate concept system designed to solve a common challenge in liquid hydrogen systems: Boil-off gas.

Their clever invention captures and reuses boil-off gas – a pesky byproduct of liquid hydrogen storage – turning what would be a waste product, into something genuinely useful.

What is boil-off gas?

Liquid hydrogen has to be stored at a frosty -253°C (that’s only 20 degrees off absolute zero!). Even with advanced insulation, some heat inevitably seeps in, causing a portion of the liquid hydrogen to evaporate back into gas form.

This is known as boil-off gas, and in most cases, it’s vented harmlessly into the atmosphere. But that’s a waste of valuable fuel, and not very Japanese.

So Toyota has developed a system to reclaim this gas, transforming it into usable energy and significantly boosting the efficiency of liquid hydrogen systems.

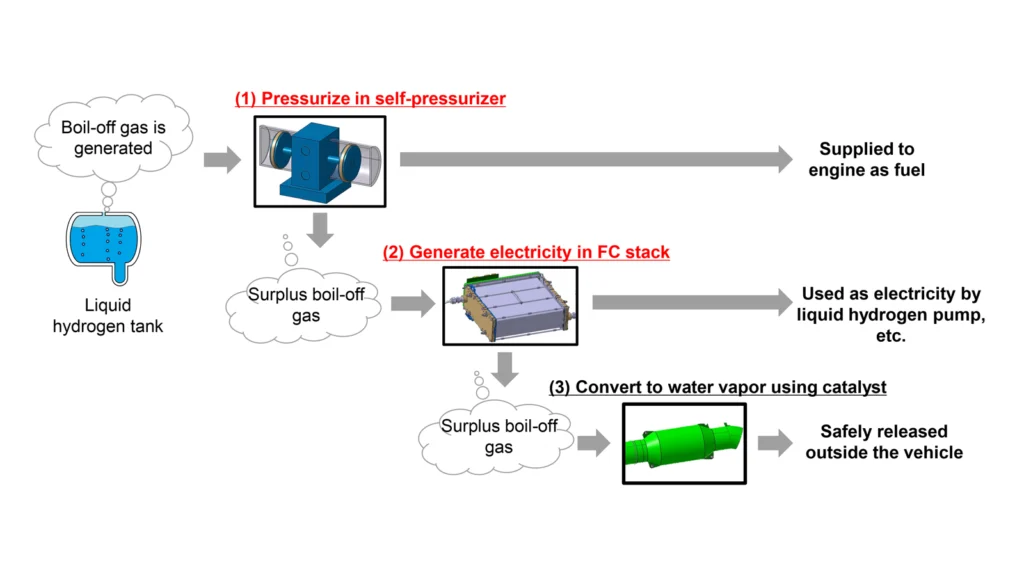

The system works as follows:

1. Converting gas back into fuel

At the core of the system is a device called the ‘self-pressuriser’. Using the natural pressure of the boil-off gas, it compresses the gas without needing an ounce of external energy – I know this sounds a bit perpetual motion-ey but trust me it’s not. This process makes the hydrogen usable as fuel again, boosting overall system efficiency.

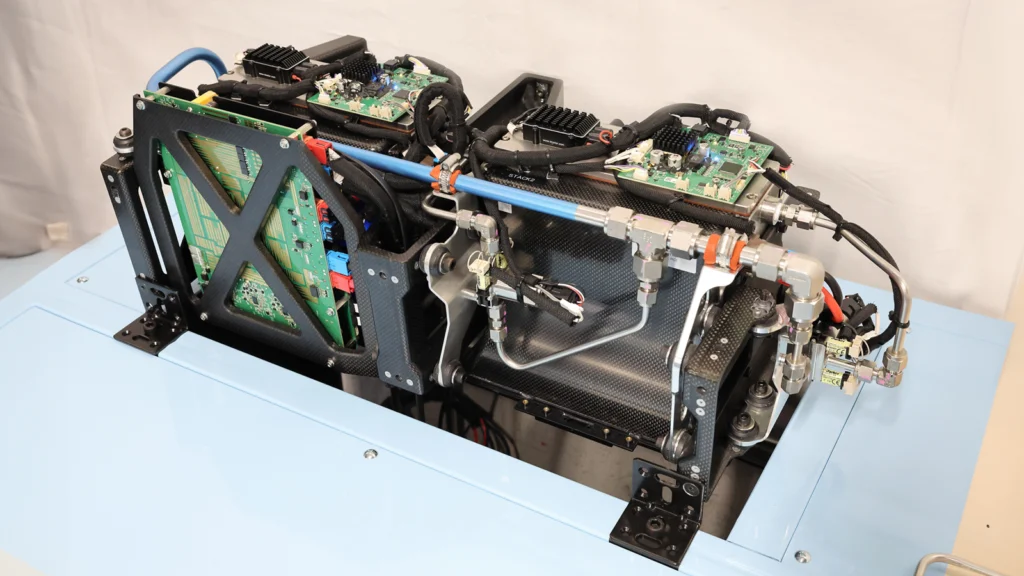

2. Generating electricity from leftovers

Not all boil-off gas can be reused as fuel, sadly. But you needn’t worry – any excess gas is fed into a compact version of a fuel cell stack, where it’s converted into electricity. This electricity can then power auxiliary systems, like the liquid hydrogen pump, for instance, or the windscreen wipers, all reducing load on the car’s alternator.

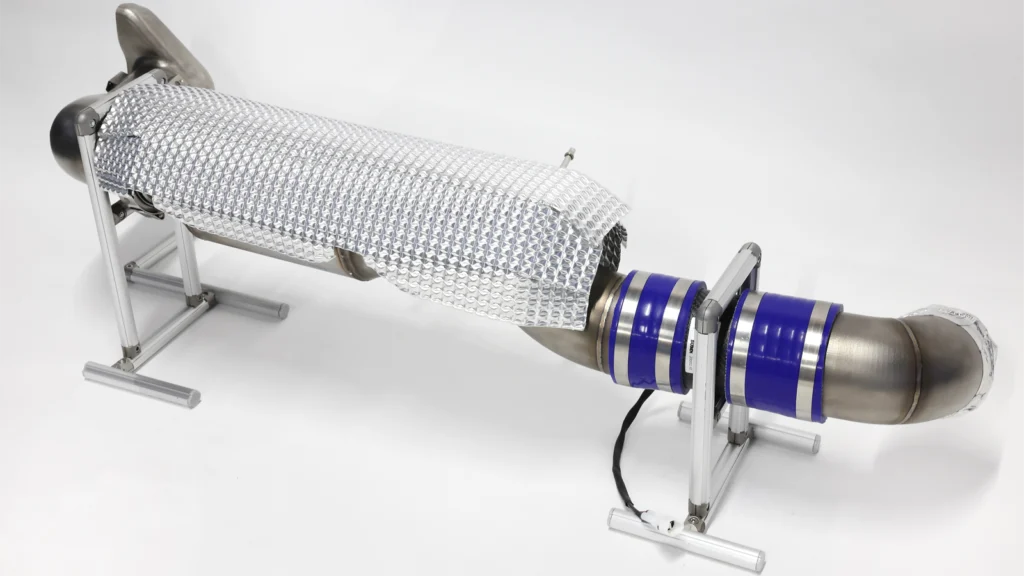

3. Safely releasing the rest

Any remaining gas that cannot be reused or converted is processed through a catalyst, transforming it into harmless H2O water vapour. No emissions, nor any risks associated with hydrogen leaks. Wonderful.

While still in the concept stage, Toyota’s system highlights their focus on tackling the practical challenges of hydrogen fuel.

By improving efficiency and reducing waste, innovations like this could make liquid hydrogen more viable across a range of applications, from motorsport to everyday transport.

Toyota is also looking for partners to help develop and scale this technology, emphasising that collaboration is key to its long-term success.

This is one of the things that is so great about motorsport. We get the thrill of wheel-to-wheel action, while the boffins work away behind the scenes on the tech that will make tomorrow’s cars better for all of us.